Blog

7 Essential Tips for Optimizing Your Cable and Harness Assembly Efficiency by 30% in 2023

In today's rapidly evolving manufacturing landscape, optimizing cable and harness assembly efficiency is crucial for staying competitive. According to a recent industry report by Technavio, the market for cable assemblies is projected to grow by USD 20.04 billion from 2023 to 2027, highlighting the increasing demand for streamlined production methods. As manufacturers seek to enhance their operational workflows, it is essential to implement strategies that can boost efficiency by as much as 30%. This blog explores seven essential tips for optimizing cable and harness assembly processes, focusing on best practices that can lead to significant improvements in productivity, quality, and cost-effectiveness. By leveraging these strategies, organizations can not only meet market demands but also lay a strong foundation for future advancements in their assembly practices.

Understanding the Importance of Cable and Harness Assembly Efficiency in 2023

In 2023, optimizing cable and harness assembly efficiency has become a critical focus for manufacturers looking to enhance productivity and reduce costs. The importance of this efficiency cannot be overstated, as streamlined processes not only minimize waste but also support faster turnaround times, ultimately improving customer satisfaction. Companies that prioritize efficiency in their assembly line are better positioned to adapt to market demands and technological advancements.

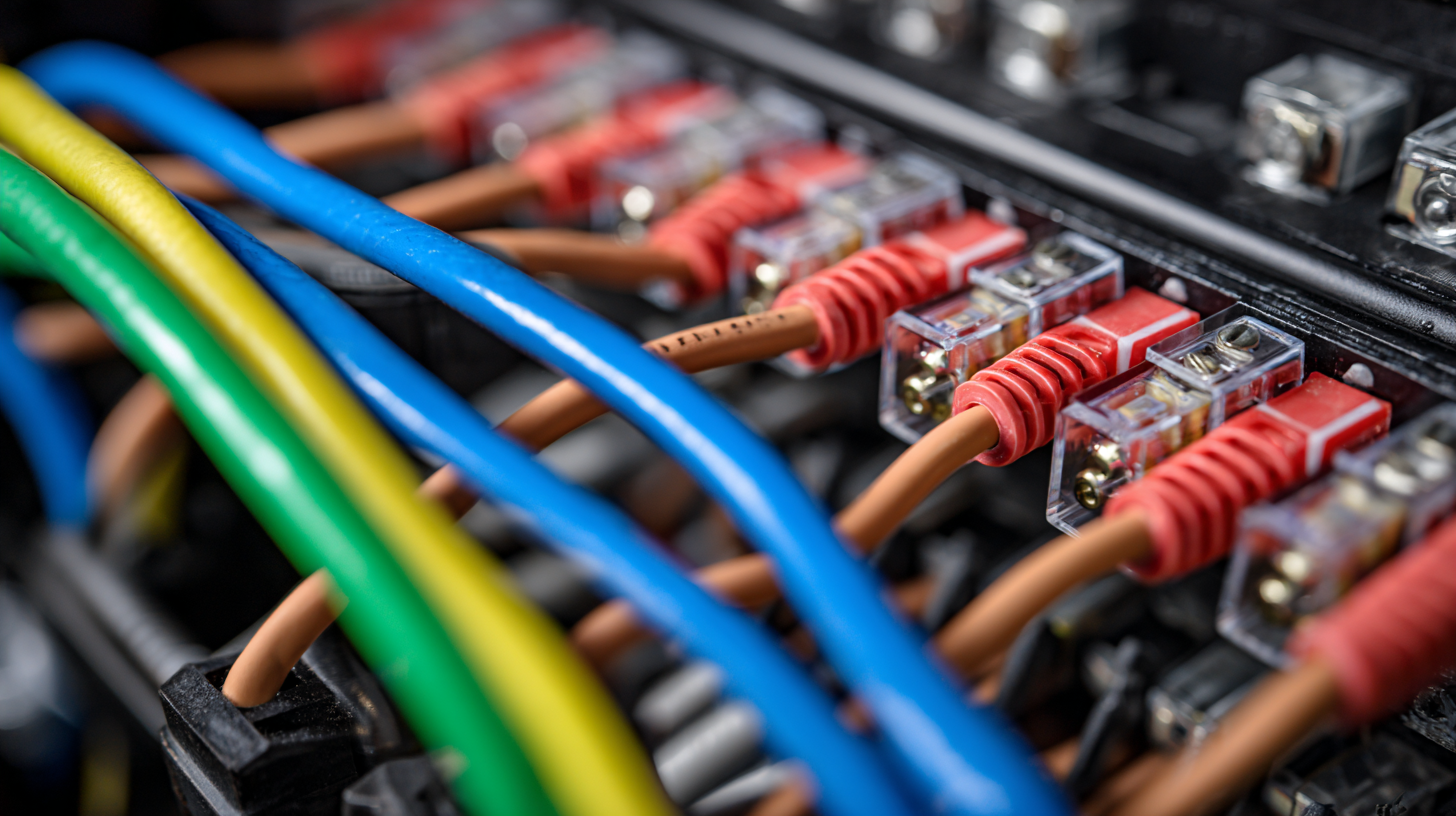

One essential tip for improving assembly efficiency is to invest in high-quality materials. By using durable and reliable components, you can decrease the likelihood of failures and rework, allowing for smoother production flows. Additionally, implementing modular designs can significantly enhance flexibility in assembly. This approach makes it easier to adapt to different configurations and customer requirements, resulting in a more efficient production process.

Furthermore, embracing automation technology can propel efficiency to new heights. Automated systems can expedite repetitive tasks, reduce human error, and ensure consistency in assembly quality. This investment in technology not only saves time but also allows skilled workers to focus on more complex tasks, ultimately leading to a 30% increase in efficiency for cable and harness assembly in 2023.

Identifying Common Challenges in Cable and Harness Assembly Processes

In the competitive landscape of cable and harness assembly, identifying common challenges is essential to enhance efficiency. One major issue is the shortage of skilled labor, which significantly impacts production timelines and quality. According to industry reports, around 75% of manufacturers cite workforce shortages as a critical barrier to meeting production goals. This gap emphasizes the importance of effective training programs to develop skilled employees who can navigate the complexities of wire harness assembly.

Another pressing challenge is the variability in costing across different production scales. Research indicates that both large and small manufacturing operations struggle with accurate cost estimation, leading to financial inefficiencies. Implementing robust enterprise resource planning (ERP) systems can address these issues by streamlining operations and improving cost projections. Additionally, the adoption of advanced automation technologies is transforming the assembly process, reducing labor intensity and minimizing human error. In fact, automating wire harness production has shown potential to increase output by up to 30%, demonstrating a clear path to improved efficiency in 2023 and beyond.

Leveraging Automation Tools for Streamlined Assembly Workflows

In an era where efficiency is paramount, leveraging automation tools in cable and harness assembly can significantly streamline workflows. Automation not only reduces manual labor but also minimizes errors, allowing teams to focus on higher-value tasks. By integrating advanced software solutions and robotics, companies can enhance precision in cutting, crimping, and testing processes, ultimately leading to superior quality and faster turnaround times.

Moreover, adopting automation accelerates the adaptability of assembly lines in response to changing demands. With the ability to swiftly reprogram machines for different tasks, businesses can reduce bottlenecks and increase production flexibility. This scalability is particularly crucial in today’s fast-paced market, where customer requirements often shift abruptly. By investing in automation technology, organizations are not just optimizing their current processes; they are also future-proofing their operations against evolving market challenges.

Implementing Best Practices for Quality Control in Cable Assemblies

In today's fast-paced manufacturing environment, ensuring quality control in cable assemblies is paramount to achieving optimal efficiency. One of the best practices is to implement a standardized inspection process at every stage of production. This not only helps in identifying defects early but also minimizes rework and scrap costs. Regular audits of the assembly process can further enhance reliability, ensuring that each component meets the specified quality standards before it becomes part of the final product.

Moreover, investing in training for employees who handle quality control is crucial. Empowering your team with knowledge about the latest technologies and industry standards enables them to spot potential issues promptly. Additionally, integrating automated testing systems can significantly streamline the quality assurance process, allowing for faster feedback and adjustments. By fostering a culture of quality and accountability, organizations can enhance the overall performance of their cable and harness assemblies, ultimately driving efficiency gains by as much as 30%.

7 Essential Tips for Optimizing Your Cable and Harness Assembly Efficiency by 30% in 2023

| Tip Number | Best Practice | Description | Expected Impact (%) |

|---|---|---|---|

| 1 | Standardize Components | Use uniform components to minimize complexity. | 10% |

| 2 | Improve Training | Enhance staff training for better assembly techniques. | 15% |

| 3 | Invest in Technology | Use automated tools for precision and speed. | 20% |

| 4 | Quality Control Checks | Implement regular quality assurance audits. | 25% |

| 5 | Optimize Layout | Arrange workspaces for optimal workflow. | 10% |

| 6 | Supplier Collaboration | Work closely with suppliers for timely materials. | 15% |

| 7 | Feedback Mechanism | Establish a system for team feedback on processes. | 20% |

Training and Developing Your Workforce for Enhanced Assembly Performance

To enhance assembly performance in cable and harness manufacturing, investing in workforce training and development is crucial. A study by the National Association of Manufacturers (NAM) found that companies with robust training programs see a 20% increase in productivity. This boost is attributed to a well-trained workforce that can efficiently handle intricate tasks and minimize errors during assembly processes. Moreover, continuous skills development helps employees adapt to rapidly evolving technologies, ensuring that the assembly techniques remain cutting-edge.

Implementing effective training strategies can significantly impact the efficiency of cable and harness assembly. According to a report from the Society of Manufacturing Engineers (SME), organizations that prioritize employee development have a 30% lower product defect rate. This reduction directly correlates with increased operational efficiency, as fewer defects lead to less rework and quicker turnaround times. By focusing on tailored training programs that emphasize both technical skills and teamwork, companies can optimize their assembly lines and realize substantial improvements in overall performance and output.

Related Posts

-

Comparing Wire Harness Assemblies: Which Cable Solutions Meet Industry Standards Best?

-

Discovering Cable Harness Assembly: Unique Examples that Drive Efficiency in Manufacturing

-

Innovative Electrical Harness Solutions for Automotive Challenges in Global Supply Chains

-

2025 Market Insights: 5 Essential Tips for Succeeding in Best Wire Harness Assembly

-

Ultimate Guide to Cable and Harness Assembly Solutions for Global Procurement Success

-

Essential Checklist for Global Buyers to Navigate the Wire and Cable Industry Trends and Standards

© 2023 JEM Electronics, Inc. – United States Cable Assembly. All rights reserved.