Blog

How to Select the Right Wire Assemblies for Your Global Supply Chain Needs

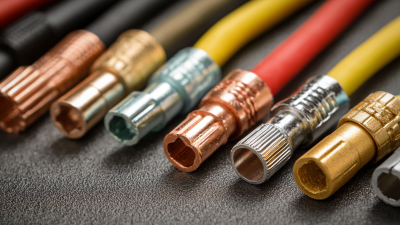

In today’s fast-paced and interconnected global marketplace, selecting the right wire assemblies is crucial for ensuring a streamlined supply chain. Wire assemblies play a vital role in the functionality and reliability of electronic systems, making their selection a pivotal aspect of product development and manufacturing. With a myriad of options available, businesses must navigate through factors such as material compatibility, compliance with international standards, and customization needs to find the perfect fit for their specific applications. This blog will explore how to effectively assess your global supply chain requirements and highlight the best practices for choosing wire assemblies that not only enhance operational efficiency but also align with your overall strategic goals. By understanding the complexities involved and leveraging the latest technologies and methodologies, companies can optimize their supply chains and achieve competitive advantage in the market.

Understanding the Importance of Wire Assemblies in Global Supply Chains

In today's interconnected world, wire assemblies play a crucial role in establishing robust global supply chains. Understanding their importance is essential for companies aiming to maintain efficiency and competitiveness in the market. As the global wire and cable materials market is projected to expand significantly, reaching approximately $244.44 billion by 2032, the proper selection of wire assemblies becomes even more vital. These components not only enhance connectivity but also support the seamless transfer of data and power across various industries.

With the increasing complexity of supply chains, businesses must prioritize quality when selecting wire assemblies. Poor-quality components can lead to operational disruptions, affecting everything from manufacturing to delivery. Furthermore, as organizations strive to meet sustainability goals, choosing suppliers that adhere to ethical practices becomes imperative. This awareness will ultimately impact the entire supply chain by fostering greater transparency and resilience. By focusing on high-quality wire assemblies, businesses can ensure that their supply chains remain agile and capable of meeting the demands of a rapidly evolving marketplace.

Key Factors to Consider When Selecting Wire Assemblies

When selecting wire assemblies for your global supply chain needs, several key factors must be considered to ensure optimal performance and efficiency. One crucial aspect is material compatibility; different applications may require specific materials to withstand environmental conditions such as temperature variations, humidity, and chemical exposure. According to a report by MarketsandMarkets, the global wire harness market is projected to grow significantly, driven by advancements in technology and demand for lightweight, high-performance components. Therefore, understanding the material properties and their implications on overall functionality is vital.

Another important factor is the manufacturing process. Whether you are looking for custom wire assemblies or standardized solutions, assessing the production capabilities and quality assurance practices of your suppliers is essential. A recent survey by IPC revealed that 65% of companies prioritize suppliers with robust quality control measures in place. By narrowing down manufacturers who follow industry best practices, you can minimize risks associated with defects and ensure compliance with international standards.

Tips: When evaluating potential suppliers, consider conducting site visits to observe their production lines and quality processes firsthand. Additionally, request certifications and test reports to verify their claims regarding reliability and performance. Lastly, don’t hesitate to engage in discussions about their capacity to handle volume fluctuations in your supply chain to ensure they align with your operational needs.

Evaluating Supplier Qualifications for Wire Assembly Needs

When selecting wire assemblies for your global supply chain needs, evaluating supplier qualifications is a critical step. The supplier's ability to provide high-quality wire assemblies can significantly impact your operations and product performance. Look for suppliers who demonstrate expertise in the specific materials required, such as PVC insulated copper wires or aluminum wires, as highlighted in recent industry reports. Understanding their manufacturing processes and quality control measures is essential.

**Tip 1:** Always request detailed documentation about the supplier's manufacturing standards and quality assurance protocols. This includes certifications and compliance with industry regulations, which can provide insights into their commitment to quality.

Additionally, consider how suppliers handle the complexity of materials and technologies they use. For example, the advancements in battery technology for electric vehicles have necessitated a keen understanding of fast charge performance, material compatibility, and thermal management. A supplier's ability to navigate these nuances can be a decisive factor.

**Tip 2:** Engage with suppliers who have experience in evolving markets and can demonstrate adaptability to new technology demands. Understanding their capacity to innovate and deliver on time will help ensure a smooth integration into your supply chain.

How to Select the Right Wire Assemblies for Your Global Supply Chain Needs - Evaluating Supplier Qualifications for Wire Assembly Needs

| Supplier Name | Location | Experience (Years) | Certifications | Production Capacity (Units/Month) | Lead Time (Days) | Customer Rating (1-5) |

|---|---|---|---|---|---|---|

| Supplier A | USA | 10 | ISO 9001, UL | 5000 | 30 | 4.8 |

| Supplier B | Germany | 15 | ISO 13485 | 8000 | 25 | 4.6 |

| Supplier C | China | 20 | ISO 9001, RoHS | 10000 | 40 | 4.5 |

| Supplier D | Japan | 12 | ISO 9001 | 6000 | 35 | 4.7 |

| Supplier E | Canada | 8 | ISO 9001, CE | 3000 | 20 | 4.9 |

Cost vs. Quality: Finding the Right Balance in Wire Assembly Selection

When selecting wire assemblies for global supply chain needs, the balance between cost and quality is pivotal. According to a report by the International Wire and Cable Association, the global demand for wire and cable is expected to reach $250 billion by 2025, highlighting the competitive nature of this industry. Companies are increasingly pressured to reduce costs while maintaining high performance and reliability standards. Therefore, striking the right balance is not merely a matter of preference; it has profound implications for supply chain efficiency and product integrity.

Quality is often associated with higher costs, but this isn't always the case. A study conducted by the Manufacturing Institute revealed that investing in quality wire assemblies can lead to a 20% reduction in failure rates and a corresponding decrease in warranty claims, which can save companies substantial amounts over the lifecycle of a product. This emphasizes the importance of conducting thorough supplier assessments and embracing technologies such as automated testing processes, which ensure that quality is not compromised amidst cost-cutting measures. Ultimately, choosing the right wire assemblies involves meticulous consideration of both cost and quality factors, ensuring a resilient and efficient supply chain.

Ensuring Compliance and Standards in Global Wire Assemblies

When selecting wire assemblies for your global supply chain, ensuring

compliance and adherence to industry standards is paramount. Different regions have varying regulations

and standards that govern the manufacture and use of wire assemblies. Compliance with these standards not

only avoids potential legal issues but also enhances the quality and reliability of the products being used.

Companies must stay informed about these regulations, such as UL (Underwriters Laboratories)

certification in North America or CE marking in Europe, which signify that products meet

safety and performance requirements.

Moreover, working closely with suppliers who understand the complexities of international standards can

streamline the selection process. It’s essential to evaluate the supplier's certification status and

adherence to industry best practices. Implementing rigorous quality control measures

during the manufacturing process ensures that the wire assemblies will perform as intended across different markets.

Emphasizing compliance and standards within your supply chain strategy not only safeguards your business's

reputation but also supports long-term operational success in a competitive global landscape.

Related Posts

-

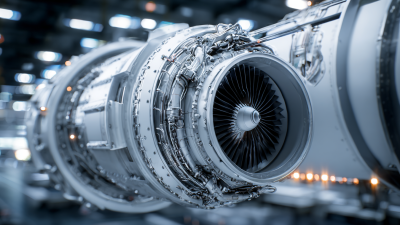

Innovative Applications of Best Wire Assemblies in Aerospace Industry

-

6 Proven Tips for Mastering Wire Assemblies in Your Projects

-

Ultimate Guide to Cable and Harness Assembly Solutions for Global Procurement Success

-

Essential Checklist for Global Buyers to Navigate the Wire and Cable Industry Trends and Standards

-

Innovative Electrical Harness Solutions for Automotive Challenges in Global Supply Chains

-

The Ultimate Guide to Choosing the Right Electrical Wire Connector for Your Projects

© 2023 JEM Electronics, Inc. – United States Cable Assembly. All rights reserved.