Blog

6 Proven Tips for Mastering Wire Assemblies in Your Projects

In today's rapidly evolving technological landscape, the demand for high-quality wire assemblies is more critical than ever. According to a recent report by MarketsandMarkets, the global wire and cable market is projected to reach $292.6 billion by 2026, driven by advancements in various sectors such as automotive, telecommunications, and consumer electronics. Mastering wire assemblies not only ensures optimal performance and reliability but also plays a significant role in enhancing overall project efficiency. Whether you’re a seasoned engineer or a DIY enthusiast, understanding the nuances of wire assembly techniques can dramatically improve the quality of your work.

In this blog, we will explore six proven tips that can help you master wire assemblies and elevate your projects to new heights, ensuring that you stay ahead of the curve in this competitive industry.

Fundamentals of Wire Assembly: Understanding Materials and Tools

When tackling wire assemblies, understanding both the materials and tools at your disposal is crucial. Different projects may require various types of wires, including stranded, solid, or specialty wires. Stranded wire, made up of many small strands, offers flexibility and durability, making it perfect for applications that require bending or movement. On the other hand, solid wire is typically used for static installations and can provide stronger connections in fixed setups. Moreover, selecting wires with appropriate insulation—like PVC, PTFE, or silicone—is essential, as the insulation affects both performance and safety.

When tackling wire assemblies, understanding both the materials and tools at your disposal is crucial. Different projects may require various types of wires, including stranded, solid, or specialty wires. Stranded wire, made up of many small strands, offers flexibility and durability, making it perfect for applications that require bending or movement. On the other hand, solid wire is typically used for static installations and can provide stronger connections in fixed setups. Moreover, selecting wires with appropriate insulation—like PVC, PTFE, or silicone—is essential, as the insulation affects both performance and safety.

Beyond materials, the right tools significantly influence the quality of your wire assemblies. A quality wire stripper, for instance, is fundamental for preparing wire ends without damaging them. Crimping tools are equally important, ensuring secure connections when attaching terminals to wires. Investing in a good soldering iron can also enhance the robustness of your assemblies by providing reliable and durable joints. Familiarizing yourself with these tools and properly utilizing them will not only streamline your assembly process but also enhance the overall performance of your projects.

Essential Techniques for Organizing and Managing Wires Effectively

When it comes to managing wires effectively within any project, organization is key. A cluttered workspace can lead to confusion, inefficiency, and even errors during assembly. Therefore, adopting essential techniques for wire organization can significantly enhance your workflow. One proven method is to use color-coded labels or tags to identify different wires and connections, making it easier to track and manage them. Additionally, utilizing cable organizers or trays can prevent tangling and help maintain a clean, orderly workspace.

In a world where digital transformations are reshaping industries, efficient wire management is more important than ever. Just as decluttering experts emphasize the importance of organized spaces in our homes, the same principles apply to technical projects. By employing simple yet effective storage solutions for wires, you can streamline your project execution and focus on innovation rather than chaos. Techniques borrowed from organizational psychology can also be beneficial; by applying strategic thinking to wire management, you can enhance overall project outcomes while minimizing stress and improving productivity.

Wire Assembly Management Techniques

Step-by-Step Guide to Creating Secure Connections in Wire Assemblies

Creating secure connections in wire assemblies is crucial for the reliability and performance of any electrical project. According to a report from the International Electrotechnical Commission (IEC), nearly 30% of electrical failures in industrial environments can be attributed to poor wire assembly practices. Thus, mastering these techniques is not just beneficial; it's essential for ensuring long-term operational safety and efficiency.

The process begins with selecting the right materials. Using high-quality wires and connectors can significantly reduce the risk of failure. A study by the Institute of Electrical and Electronics Engineers (IEEE) found that using proper insulation and conductor materials can increase connection durability by up to 50%. Additionally, applying consistent pressure during connections, whether through soldering or crimping, ensures a strong bond that can withstand vibrations and thermal expansion. Following step-by-step guidelines, like maintaining clean work surfaces and regularly inspecting for signs of wear or damage, will help you achieve secure and reliable wire assemblies every time.

6 Proven Tips for Mastering Wire Assemblies in Your Projects - Step-by-Step Guide to Creating Secure Connections in Wire Assemblies

| Tip Number | Tip Description | Tools Needed | Expected Outcome |

|---|---|---|---|

| 1 | Use quality connectors to ensure reliable connections. | Wire strippers, crimping tool | Higher durability and safety in connections. |

| 2 | Strip the wires correctly to match the connector size. | Wire strippers | Proper fit for optimal conductivity. |

| 3 | Twist wires before crimping for added strength. | Pliers | Better mechanical connection, reduced risk of failure. |

| 4 | Terminating wires properly to avoid shorts. | Heat shrink tubing, electrical tape | Reduced risk of short circuits and electrical failures. |

| 5 | Keep wire lengths consistent for easier troubleshooting. | Measuring tape | Easier identification of issues in the assembly. |

| 6 | Test connections before finalizing the assembly. | Multimeter | Ensured functionality and avoided future issues. |

Common Mistakes in Wire Assembly and How to Avoid Them

Wire assemblies are crucial in various industries, yet common mistakes can lead to project failures and increased costs. According to a recent study by the International Wire Association, improper wire preparation is responsible for over 30% of assembly failures. This includes issues such as inadequate stripping techniques, which can lead to wire damage and reduced electrical conductivity. It's essential to invest time in understanding the correct methods for stripping and preparing wires to ensure optimal performance.

Another prevalent mistake is the mismanagement of connectors. The Connector Supplier reports that nearly 25% of connector failures stem from incorrect mating and poor alignment during assembly. This not only affects the assembly's overall reliability but also results in time-consuming rework and increased labor costs. To avoid such pitfalls, employing guides and checklists during the connector assembly process can be invaluable. Adopting these practices not only enhances the quality of wire assemblies but also significantly mitigates risks associated with electrical failures in projects.

Testing and Troubleshooting Your Wire Assemblies for Optimal Performance

When it comes to wire assemblies, testing and troubleshooting are paramount to ensuring optimal performance in any project. According to a report by the Electronics Technical Association, poor assembly quality can lead to a staggering 30% increase in failure rates, significantly impacting both reliability and project costs. Implementing rigorous testing methods, such as continuity testing and insulation resistance measurements, can identify potential issues before they escalate, ensuring that your assemblies perform as expected.

Moreover, addressing common troubleshooting challenges can save time and resources. The International Society of Automation highlights that systematic troubleshooting can reduce the time spent on resolving wire assembly issues by as much as 40%. By employing tools like multimeters for voltage testing and using thermal imaging to detect hotspots, engineers can quickly pinpoint discrepancies and make necessary adjustments. Leveraging such proactive strategies fosters enhanced reliability and longevity in wire assemblies, ultimately leading to successful project outcomes.

Related Posts

-

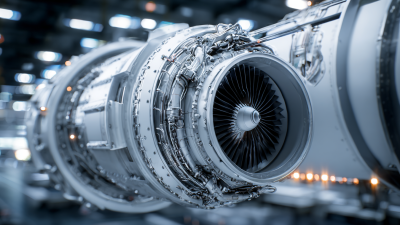

Innovative Applications of Best Wire Assemblies in Aerospace Industry

-

Comparing Wire Harness Assemblies: Which Cable Solutions Meet Industry Standards Best?

-

Discovering Cable Harness Assembly: Unique Examples that Drive Efficiency in Manufacturing

-

2025 Market Insights: 5 Essential Tips for Succeeding in Best Wire Harness Assembly

-

Essential Checklist for Global Buyers to Navigate the Wire and Cable Industry Trends and Standards

-

Innovative Electrical Harness Solutions for Automotive Challenges in Global Supply Chains

© 2023 JEM Electronics, Inc. – United States Cable Assembly. All rights reserved.