Blog

How to Optimize Harness Assembly Efficiency: Insights from Industry Data on Production Rates and Quality Control

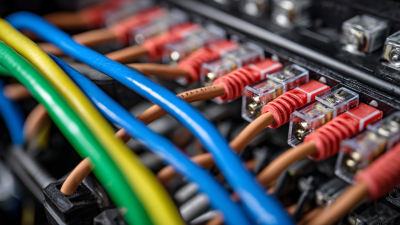

In the competitive landscape of manufacturing, optimizing harness assembly efficiency is crucial for maintaining productivity and ensuring high-quality outputs. As industries strive to meet increasing demands, understanding the interplay between production rates and stringent quality control measures becomes vital. This article delves into insightful industry data that highlights best practices for enhancing the harness assembly process. By examining key performance indicators and effective quality management strategies, we aim to provide actionable recommendations that can significantly improve efficiency.

Furthermore, understanding the nuances of harness assembly not only empowers manufacturers to streamline operations but also fosters innovation in design and implementation. This comprehensive approach ensures that businesses can adapt to evolving market needs while delivering products that meet rigorous quality standards.

Strategies for Enhancing Production Rates in Harness Assembly Processes

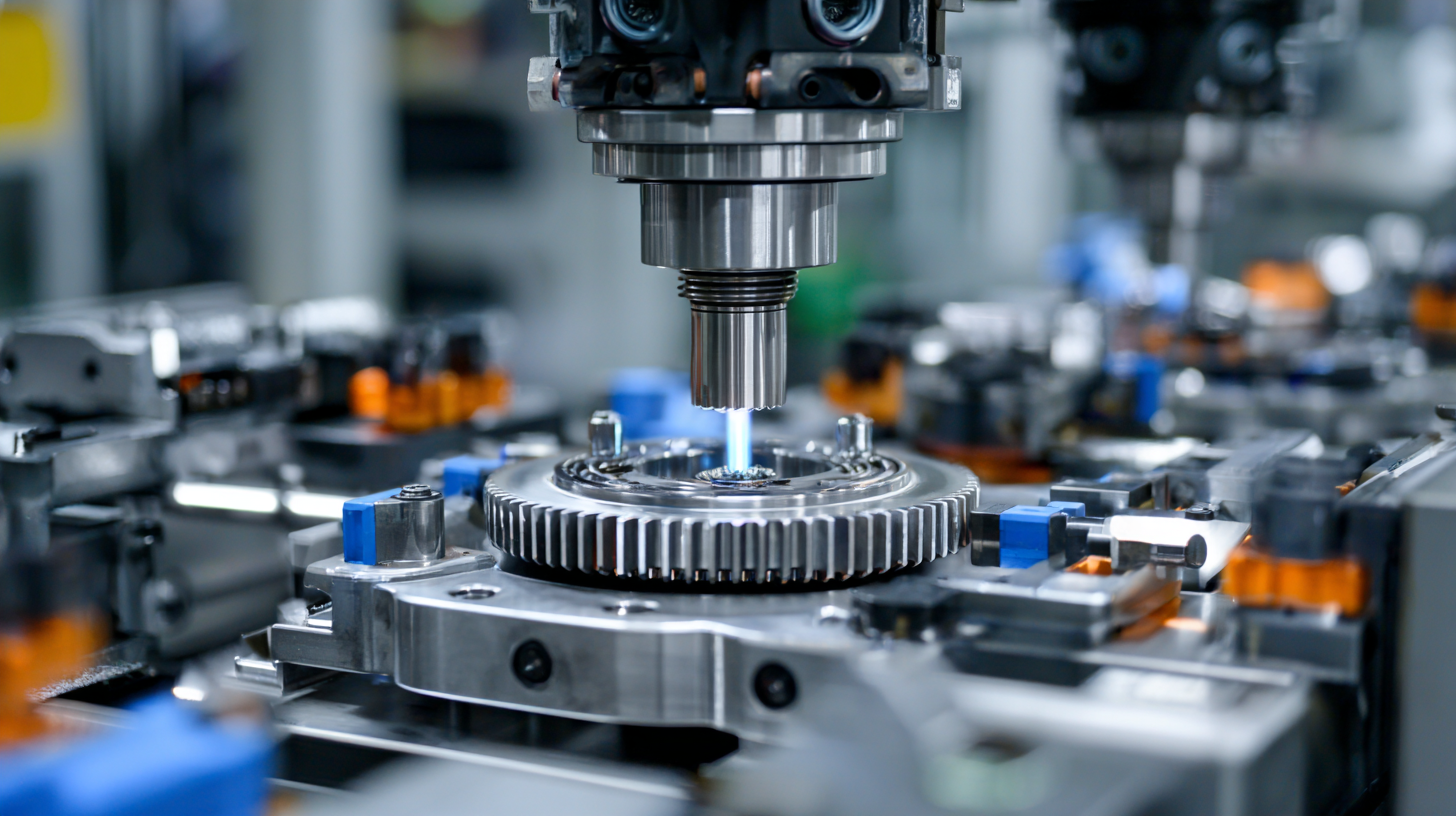

Enhancing production rates in harness assembly processes is vital for driving efficiency and maintaining high-quality standards in manufacturing. One of the most effective strategies is to streamline workflow through the implementation of Lean manufacturing principles. By eliminating waste, optimizing resource allocation, and improving the layout of work stations, manufacturers can significantly reduce cycle times and boost overall output.

Tips:

Ensure that tools and materials are organized and easily accessible at each assembly station. This minimizes downtime and keeps production moving smoothly. Regular training sessions for assembly workers can also improve their skills and efficiency, leading to faster assembly times.

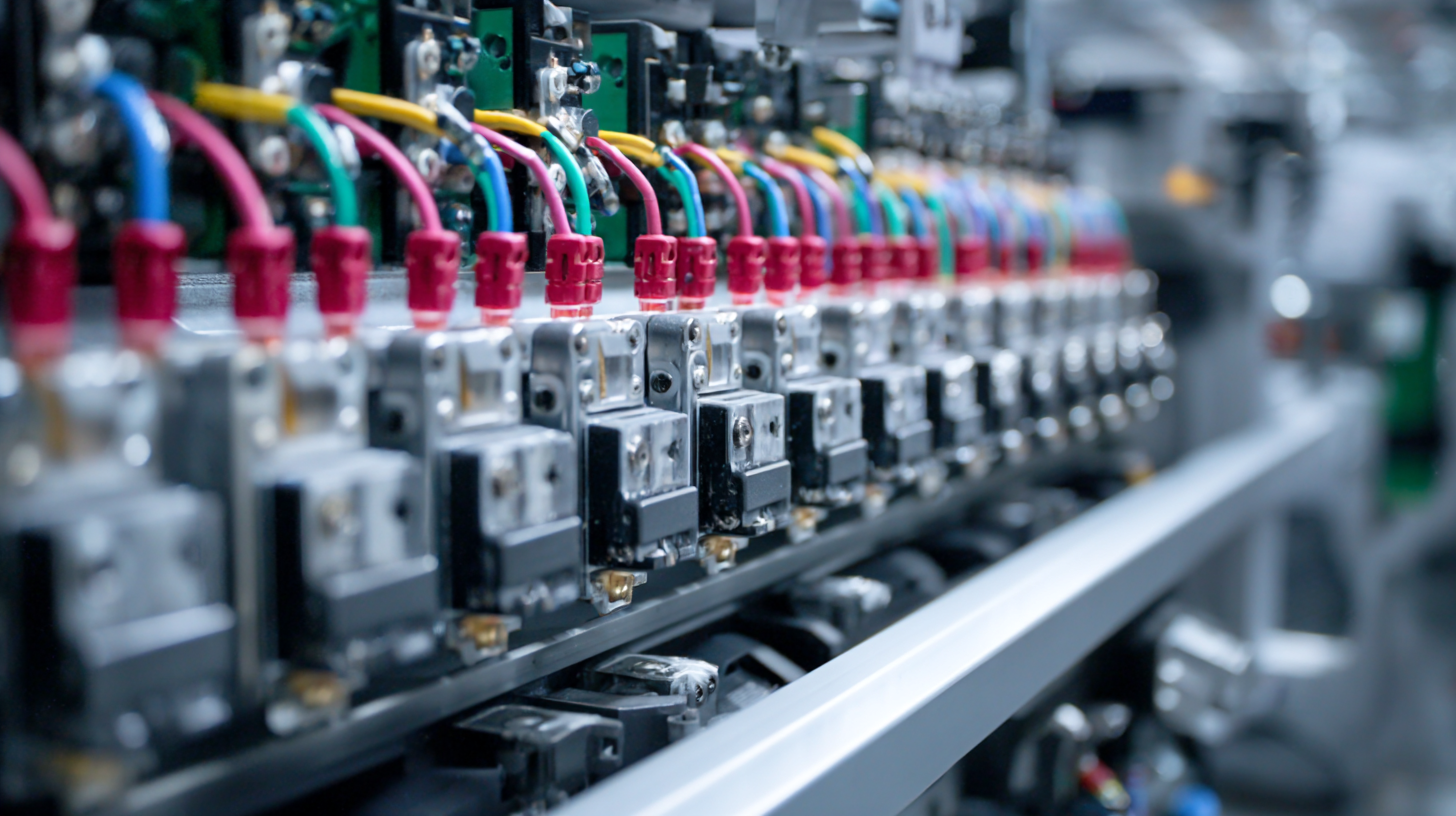

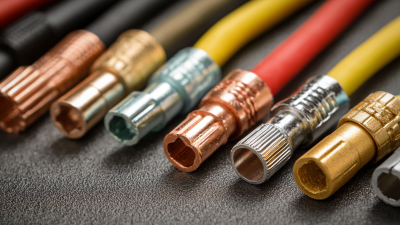

Another key approach is to leverage technology and automation. Advanced machinery, such as automated wire strippers and crimping tools, can enhance precision and speed, reducing the likelihood of errors that slow down production. Additionally, incorporating real-time data tracking can help identify bottlenecks and areas for improvement, allowing for quick adjustments in the assembly line process.

Tips:

Consider investing in a digital dashboard that monitors production metrics and quality control in real time. This not only aids in maintaining production rates but also ensures that any issues can be addressed proactively, preserving high standards of quality throughout the harness assembly process.

Analyzing Quality Control Metrics to Minimize Defects and Rework

Effective quality control is crucial for optimizing harness assembly efficiency, as it directly impacts production rates and the minimization of defects and rework. By closely analyzing quality control metrics, manufacturers can pinpoint areas where errors frequently occur and develop strategies to address them. This analysis includes tracking defect rates, identifying common failure modes, and assessing the impact of these failures on overall production timelines.

Implementing a robust quality control system involves setting clear benchmarks and utilizing statistical process control (SPC) techniques. Regular audits and inspections can help in monitoring compliance with these benchmarks, allowing teams to react swiftly to deviations that may lead to defects. Furthermore, employing advanced technologies such as automated inspection systems can enhance the accuracy of quality assessments, ultimately contributing to reduced rework and increased overall efficiency in the harness assembly process.

Implementing Lean Manufacturing Principles to Streamline Assembly Operations

Implementing lean manufacturing principles is essential for optimizing harness assembly efficiency and addressing production challenges. According to a report by the Lean Enterprise Institute, organizations that adopt lean methodologies can reduce their lead time by up to 50%, while simultaneously increasing productivity by 30% or more. These principles encourage a systematic approach to eliminating waste, enhancing workflow, and improving overall quality control in assembly operations.

Implementing lean manufacturing principles is essential for optimizing harness assembly efficiency and addressing production challenges. According to a report by the Lean Enterprise Institute, organizations that adopt lean methodologies can reduce their lead time by up to 50%, while simultaneously increasing productivity by 30% or more. These principles encourage a systematic approach to eliminating waste, enhancing workflow, and improving overall quality control in assembly operations.

One key aspect of lean manufacturing is the focus on continuous improvement and value stream mapping. By analyzing every step of the assembly process, manufacturers can identify bottlenecks and redundancies that slow down production. A case study from the Society of Manufacturing Engineers highlighted how a leading harness assembly company implemented these practices, resulting in a 20% decrease in assembly time and a notable reduction in defects. This data emphasizes that applying lean techniques not only streamlines operations but also significantly bolsters product quality, leading to improved customer satisfaction and reduced costs.

Utilizing Data Analytics for Real-Time Monitoring of Production Efficiency

In today's fast-paced manufacturing environment, optimizing harness assembly efficiency is paramount. By incorporating data analytics into real-time monitoring, companies can gain valuable insights into production processes. This technology allows for continuous assessment of key performance indicators such as production rates, defect rates, and assembly times. With this information at hand, managers can identify bottlenecks and inefficiencies almost instantly, allowing for immediate corrective actions.

Furthermore, real-time data analytics facilitate proactive quality control measures. By tracking quality metrics on the assembly line, manufacturers can detect variations or anomalies early in the process, preventing potential issues from escalating. This not only enhances the overall quality of the products but also reduces waste and rework, ultimately leading to improved profitability. The integration of data-driven insights into production workflows empowers teams to make informed decisions, fostering a culture of continuous improvement and operational excellence.

Optimizing Harness Assembly Efficiency: Production Rates and Quality Control

This chart illustrates the production rates and quality control metrics over a series of weeks, helping to identify trends in assembly efficiency.

Integrating Automation Technologies to Boost Harness Assembly Workflow

The integration of automation technologies in harness assembly workflows can significantly enhance production efficiency and quality control. By leveraging advanced robotics and machine learning algorithms, manufacturers can streamline repetitive tasks, allowing human operators to focus on more complex and value-added activities. Automated assembly lines can reduce cycle times and minimize errors, leading to improved production rates. Moreover, real-time data analytics enable continuous monitoring of assembly processes, ensuring that quality standards are consistently met.

Furthermore, automation not only speeds up the assembly process but also enhances consistency and precision. Automated systems can handle intricate wiring configurations and adapt quickly to changes in design specifications. This flexibility allows manufacturers to respond faster to market demands while maintaining high quality. Investing in automation technologies, therefore, represents a strategic move for companies aiming to optimize their harness assembly operations and remain competitive in a rapidly evolving industry.

Related Posts

-

The Ultimate Guide to Choosing the Right Electrical Wire Connector for Your Projects

-

Discovering Cable Harness Assembly: Unique Examples that Drive Efficiency in Manufacturing

-

2025 Market Insights: 5 Essential Tips for Succeeding in Best Wire Harness Assembly

-

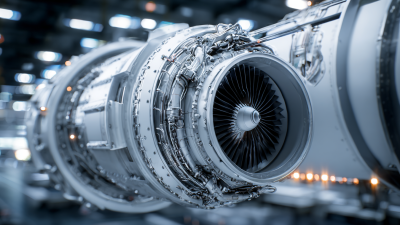

Innovative Applications of Best Wire Assemblies in Aerospace Industry

-

10 Best Industrial Wire Trends You Should Know in 2023

-

7 Essential Tips for Optimizing Your Cable and Harness Assembly Efficiency by 30% in 2023

© 2023 JEM Electronics, Inc. – United States Cable Assembly. All rights reserved.