Blog

How to Efficiently Design Your Own Wire Harness Assembly

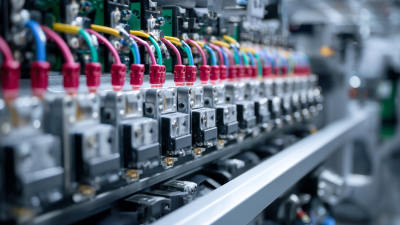

Designing an efficient wire harness assembly is pivotal in the electronics and automotive industries, where optimal performance and reliability are paramount. According to industry reports from Research and Markets, the global wire harness market is projected to reach $72.9 billion by 2027, driven by the increasing complexity of electrical systems in vehicles and consumer electronics.

A well-designed wire harness assembly not only improves the overall efficiency of these systems but also reduces the likelihood of defects and production costs. By understanding the key factors in wire harness design—such as material selection, layout optimization, and standardization—manufacturers can streamline their production processes while ensuring compliance with industry standards. As demands for more sophisticated electrical solutions rise, mastering the art of wire harness assembly design becomes essential for staying competitive in the market.

Designing an efficient wire harness assembly is pivotal in the electronics and automotive industries, where optimal performance and reliability are paramount. According to industry reports from Research and Markets, the global wire harness market is projected to reach $72.9 billion by 2027, driven by the increasing complexity of electrical systems in vehicles and consumer electronics.

A well-designed wire harness assembly not only improves the overall efficiency of these systems but also reduces the likelihood of defects and production costs. By understanding the key factors in wire harness design—such as material selection, layout optimization, and standardization—manufacturers can streamline their production processes while ensuring compliance with industry standards. As demands for more sophisticated electrical solutions rise, mastering the art of wire harness assembly design becomes essential for staying competitive in the market.

Understanding the Basics of Wire Harness Assembly Design

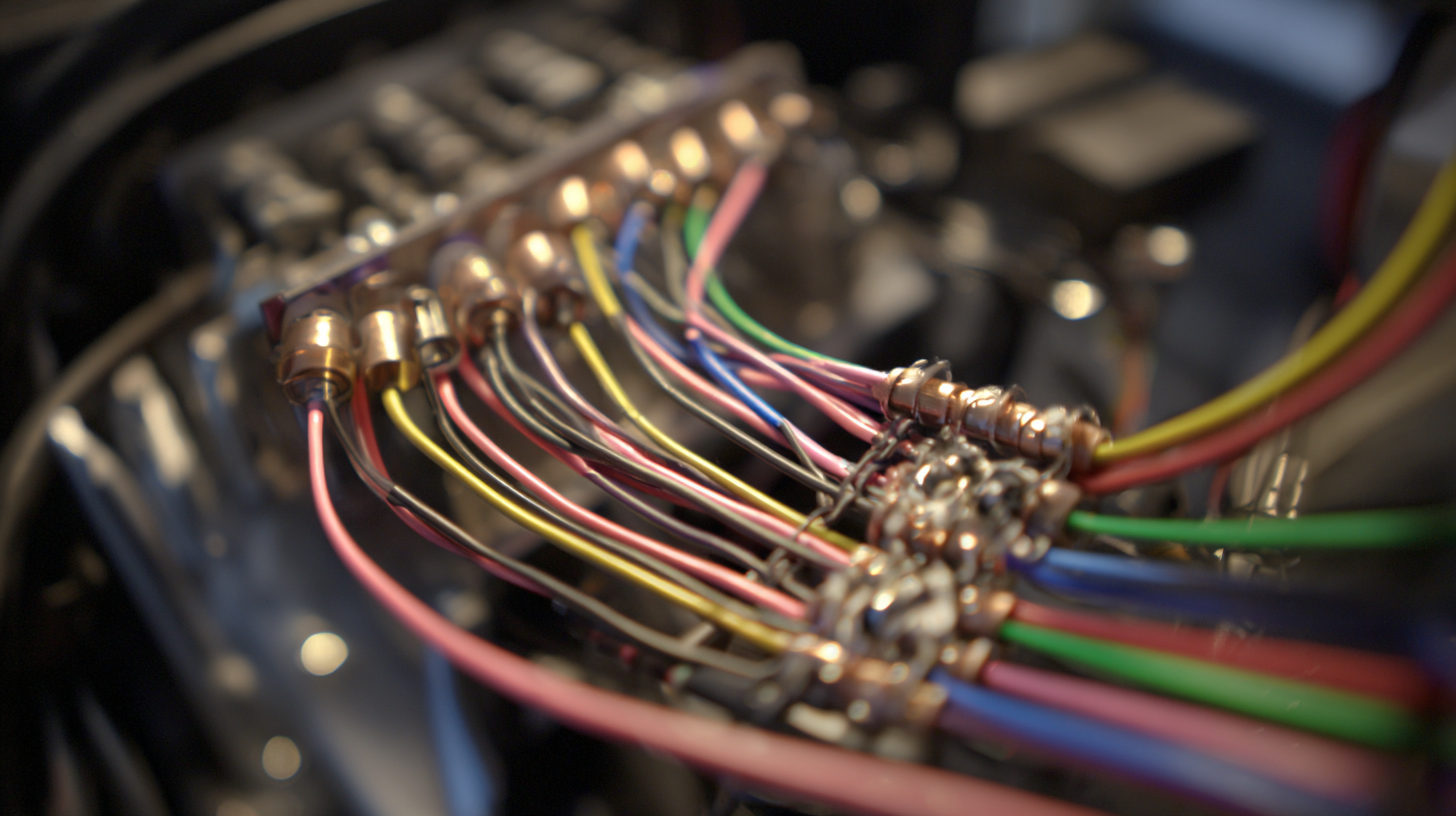

Wire harness assembly design is a critical component in various industries, including automotive, aerospace, and consumer electronics. It serves as the backbone for electrical connections, enabling the efficient transmission of power and signals. According to a report by Grand View Research, the global wire harness market is expected to reach $68.4 billion by 2025, growing at a compound annual growth rate (CAGR) of 4.6%. This underscores the growing importance of adept wire harness design in meeting the evolving demands of technology.

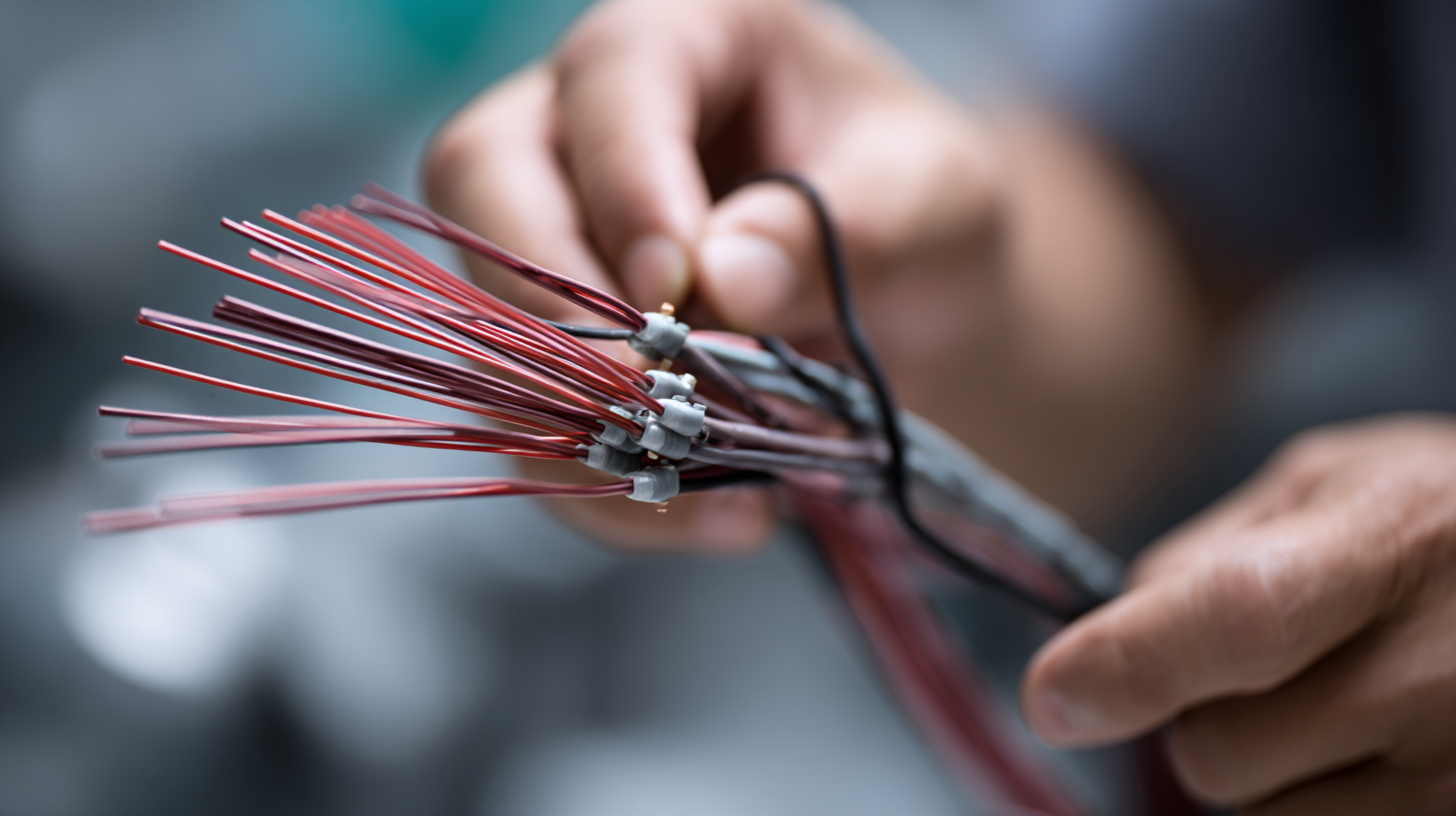

Understanding the basics of wire harness assembly involves familiarity with materials, components, and manufacturing processes. For instance, the choice of insulation material, such as PVC or cross-linked polyethylene, can significantly impact durability and performance under various environmental conditions. Furthermore, the intricacy of the assembly process, from selecting the appropriate connectors to ensuring precise routing and strain relief, is crucial to enhance the harness's reliability and efficiency. According to industry standards, a well-designed wire harness can reduce assembly time by as much as 30%, highlighting the importance of strategic planning and design in optimizing production processes.

Essential Tools and Materials for Wire Harness Assembly

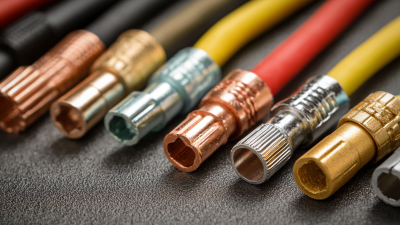

When it comes to designing your own wire harness assembly efficiently, having the right tools and materials is crucial. Start with a quality set of wire strippers and crimpers, as these will help you prepare wires and secure connections effectively. A heat gun is also essential for shrinking tubing, ensuring that your connections are insulated and protected from moisture and wear. Additionally, investing in a quality multimeter will allow you to test continuity and check for shorts, providing peace of mind in your assembly.

**Tips:** When selecting wires, consider the gauge you need based on the current load and application. For connectors, choose reliable types that suit the environment—weather-resistant options are best for outdoor use. Also, organizing your workspace with labels can save time during assembly and troubleshooting.

Don't overlook the importance of quality materials such as heat shrink tubing, which enhances the durability of your assembly. Using a variety of colors for your wires can help in identifying circuits and ensuring an organized layout. Lastly, having a schematic diagram can guide your assembly process, making it more efficient and less prone to errors.

Wire Harness Assembly: Essential Tools and Materials Usage

Step-by-Step Process for Designing Your Wire Harness

Designing your own wire harness assembly can be a complex task, but by following a structured step-by-step process, you can streamline the operation and achieve optimal results. Start by gathering all necessary specifications, including the dimensions, electrical requirements, and environmental considerations. This initial planning stage is crucial as it sets the foundation for the entire assembly.

**Tips:** When collecting your specifications, make sure to involve all stakeholders. This ensures that you cover any unique requirements and prevents potential issues later on in the design phase.

Next, create a detailed schematic of your wire harness. This should include all connections, wire types, lengths, and terminal details. Using CAD software might be beneficial at this stage, as it allows for easy adjustments and precise measurements. Pay close attention to the routing paths and how they’ll interact with surrounding components to avoid interference once the product is assembled.

**Tips:** Consider using color-coded wires to simplify the assembly process and enhance troubleshooting efficiency. This small change can make a significant difference in the long run.

Finally, prototype your wire harness assembly to test its functionality and durability. This step allows you to identify any potential issues before full-scale production, saving time and resources. Adjust the design based on feedback from testing to ensure that your wire harness meets all operational demands.

How to Efficiently Design Your Own Wire Harness Assembly - Step-by-Step Process for Designing Your Wire Harness

| Step | Description | Tools Required | Estimated Time (hours) |

|---|---|---|---|

| 1 | Define the requirements and specifications for the wire harness. | Specification Document | 1 |

| 2 | Create a schematic diagram for the wire harness layout. | CAD Software | 2 |

| 3 | Select the appropriate materials and components. | Catalogs, Suppliers | 1.5 |

| 4 | Design connectors and routing paths. | Wire Harness Design Software | 2 |

| 5 | Develop the prototype and test the assembly. | Testing Equipment | 3 |

| 6 | Finalize the design based on test results and make adjustments. | Design Review Tools | 2 |

| 7 | Prepare production documentation and assembly instructions. | Document Management Software | 1.5 |

Common Pitfalls to Avoid in Wire Harness Assembly Design

When designing a wire harness assembly, one of the most common pitfalls is neglecting the importance of proper planning and schematics. Without a clear layout, wires can become tangled, leading to difficulties in assembly and maintenance. It is essential to create detailed diagrams that outline the routing of wires, connections, and component placements. This preemptive measure can save time and reduce errors when moving from design to production.

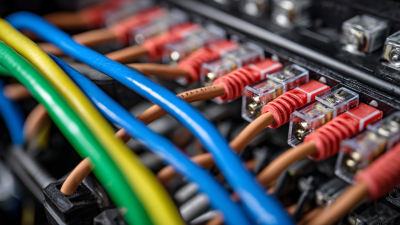

Another frequent mistake involves overlooking the specifications and tolerances for materials used in the harness. Choosing components that do not meet the required standards can result in failures during operation. Additionally, it is crucial to consider environmental factors that might affect the wires, such as heat, moisture, and vibration. Selecting the right insulation and connectors based on these considerations can greatly enhance the durability and efficiency of the wire harness, ultimately leading to a more reliable final product.

Best Practices for Testing and Quality Assurance in Wire Harnesses

Testing and quality assurance are critical components in the production of wire harness assemblies. To ensure optimal performance and reliability, manufacturers must implement rigorous testing procedures throughout the assembly process. This involves initial inspections of materials, where wire gauges, insulation types, and connector quality are evaluated to meet specified standards. Employing automated testing equipment can enhance precision, allowing for thorough continuity tests and insulation resistance checks to detect any faults early in the assembly.

In addition to pre-production testing, it is essential to formulate a detailed quality assurance plan that includes validation of the final assembly. This can involve environmental testing, such as thermal cycling and vibration tests, to simulate real-world conditions. Regular audits of the production process can help identify potential areas of improvement and ensure compliance with industry standards. Engaging in continuous feedback loops between production teams and quality assurance personnel fosters a culture of accountability, leading to enhanced product quality and customer satisfaction in wire harness assemblies.

Related Posts

-

2025 Market Insights: 5 Essential Tips for Succeeding in Best Wire Harness Assembly

-

The Ultimate Guide to Choosing the Right Electrical Wire Connector for Your Projects

-

Comparing Wire Harness Assemblies: Which Cable Solutions Meet Industry Standards Best?

-

7 Essential Tips for Optimizing Your Cable and Harness Assembly Efficiency by 30% in 2023

-

How to Optimize Harness Assembly Efficiency: Insights from Industry Data on Production Rates and Quality Control

-

Essential Checklist for Global Buyers to Navigate the Wire and Cable Industry Trends and Standards

© 2023 JEM Electronics, Inc. – United States Cable Assembly. All rights reserved.