Blog

Comparing Wire Harness Assemblies: Which Cable Solutions Meet Industry Standards Best?

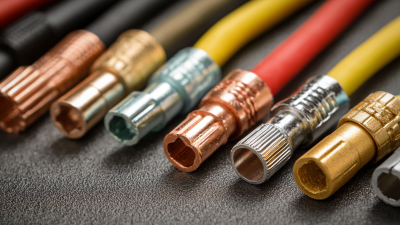

In the evolving landscape of technology and manufacturing, the importance of high-quality cable and harness assembly cannot be overstated. These assemblies play a crucial role in ensuring optimal performance and safety across various industries, from automotive to aerospace. However, with a vast array of materials, designs, and standards available, determining which cable solutions truly meet industry benchmarks can be a daunting task. This blog aims to dissect the complexities associated with wire harness assemblies, highlighting common problems and offering insights into best practices.

We will explore key factors influencing the selection process, the challenges arising from subpar components, and ultimately guide you in identifying the most reliable options for your specific applications. Join us as we navigate the intricate world of cable and harness assembly to help you make informed decisions that enhance your operational efficiency and product reliability.

Analyzing Different Types of Wire Harness Assemblies for Efficiency

When analyzing different types of wire harness assemblies for efficiency,

it's essential to consider factors such as material selection,

assembly techniques, and

design integrity. Each component of the wire harness plays a crucial role in ensuring

that the final product meets industry standards. For instance, using high-quality insulation materials can

minimize signal loss and improve the overall durability of the assembly.

Tip: Always opt for components that are rated for the specific environmental conditions

they will encounter, such as high temperatures or moisture. This will enhance the longevity and reliability

of your wire harness.

Additionally, efficient wire harness assemblies often incorporate modular designs. These designs facilitate easier

upgrades and repairs, minimizing downtime and reducing costs in the long run. Emphasizing proper layout and

organization within the harness not only simplifies the assembly process but also enhances performance

by reducing the risk of interference between wires.

Tip: Implement color-coding and labeling systems for wires and

connections within the harness. This practice can drastically improve maintenance and troubleshooting, ensuring

that identifying issues is quick and straightforward.

Key Industry Standards for Cable Solutions and Their Importance

In the rapidly evolving landscape of cable solutions, adherence to industry standards is paramount. Key standards such as IEC, UL, and BS are essential for ensuring safety, reliability, and performance of wire harness assemblies. For instance, fire-resistant cables, with insulation materials like Low Smoke Zero Halogen (LSZH), are increasingly critical as the market is projected to grow significantly, reflecting a rising demand for safer cable solutions. Analysts forecast that the fire-resistant cable market will expand considerably, driven by stringent regulations and increased awareness of safety in both residential and industrial sectors.

When evaluating cable solutions, it’s important to consider innovative testing tools. The emergence of advanced network cable testers is a testament to this. With features such as PoE testing and cable certification, these devices help ensure compliance with relevant standards, thus minimizing network failures and downtime. In fact, the UK market is seeing a trend toward adopting these testers as businesses prioritize network integrity and performance.

**Tip:** Regularly review and update your cable solutions to comply with the latest industry standards, and invest in high-quality testing tools to ensure ongoing safety and performance. Additionally, considering the size of the Data Center Wire Cable market, projected to grow to USD 30.12 billion by 2034, organizations should strategically plan their cabling investments to align with future demands and regulatory requirements.

Evaluating Performance: How Wire Harness Assemblies Meet Safety Standards

When it comes to wire harness assemblies, meeting safety standards is paramount for ensuring reliability in various industries. The evaluation of these assemblies revolves around their performance, particularly how well they adhere to established regulations such as UL, ISO, and IEC standards. These certifications not only validate the safety of the components but also reflect the assembly processes employed during manufacturing. A high-quality wire harness must be able to withstand environmental stresses, including heat, vibration, and moisture, while maintaining electrical integrity.

Moreover, performance assessment is critical in understanding how well wire harness assemblies operate in real-world applications. Factors such as insulation quality, wire gauge, and connector reliability directly influence the durability and safety of the assemblies. Rigorous testing methods, including thermal cycling and mechanical stress tests, are essential to ascertain compliance with safety standards. By focusing on these performance metrics, manufacturers can guarantee that their wire harness assemblies provide not only safety but also efficiency and longevity in their respective applications.

Comparative Benefits of Custom vs. Pre-Configured Cable Solutions

When it comes to wire harness assemblies, the choice between custom and pre-configured cable solutions can significantly impact efficiency and compliance with industry standards. Custom cable solutions offer tailored designs that meet specific requirements for a project, enabling manufacturers to optimize performance and integrate seamlessly with their systems. According to a report by MarketsandMarkets, the global market for custom cable assemblies is projected to reach $32.3 billion by 2026, driven by the increasing demand for specialized configurations in industries such as automotive, aerospace, and medical.

On the other hand, pre-configured cable solutions come with the advantages of faster turnaround times and reduced costs. A study from ResearchAndMarkets highlights that pre-assembled cable harnesses can decrease production time by up to 30%, allowing companies to respond rapidly to market needs. However, they may not always address specific application demands, which can lead to limitations in performance and adaptability in the long term. Ultimately, the decision between custom and pre-configured solutions should be based on a thorough assessment of both immediate project requirements and future scalability options.

Comparing Wire Harness Assemblies: Which Cable Solutions Meet Industry Standards Best?

| Feature | Custom Cable Solutions | Pre-Configured Cable Solutions |

|---|---|---|

| Flexibility | High | Low |

| Lead Time | Longer | Shorter |

| Cost | Higher | Lower |

| Compliance with Standards | Tailored to Specific Standards | General Standards |

| Scalability | Customizable for Large Orders | Limited to Stock Availability |

| Technical Support | Personalized Support | Standard Support |

| Use Cases | Specific Applications | General Applications |

Choosing the Right Material: Impact on Durability and Compliance

When selecting wire harness assemblies, the choice of materials significantly impacts both durability and compliance with industry standards. Common materials like PVC and TPE are widely used due to their excellent flexibility and resistance to harsh environmental conditions. According to a report from the International Wire and Cable Symposium, cables made with high-quality TPE have shown up to a 50% increase in resistance to abrasion compared to traditional PVC options, leading to longer service life and reduced replacement costs.

Moreover, compliance with industry standards such as UL, IEC, and ISO is paramount in determining the reliability of electrical connections. For instance, a study by the Institute of Electrical and Electronics Engineers (IEEE) indicates that wire harness assemblies utilizing materials that meet these standards can reduce failure rates by as much as 30%, enhancing overall system performance. Selecting the right materials not only ensures compliance but also provides additional safety against environmental factors, making it crucial for engineers to carefully evaluate their choices in the design phase.

Related Posts

-

2025 Market Insights: 5 Essential Tips for Succeeding in Best Wire Harness Assembly

-

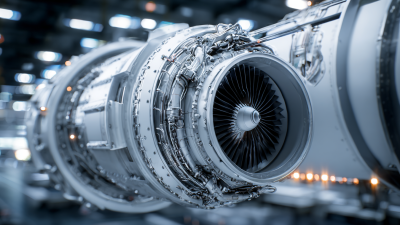

Innovative Applications of Best Wire Assemblies in Aerospace Industry

-

Innovative Electrical Harness Solutions for Automotive Challenges in Global Supply Chains

-

The Ultimate Guide to Choosing the Right Electrical Wire Connector for Your Projects

-

Ultimate Guide to Cable and Harness Assembly Solutions for Global Procurement Success

© 2023 JEM Electronics, Inc. – United States Cable Assembly. All rights reserved.