Blog

Discovering Cable Harness Assembly: Unique Examples that Drive Efficiency in Manufacturing

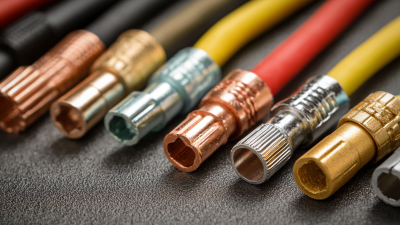

In today's manufacturing landscape, the significance of cable harness assembly cannot be overstated, as it serves as a critical component in ensuring the efficient operation of various electronic systems across multiple industries. According to recent studies, the global cable assembly market is projected to reach USD 249.34 billion by 2026, reflecting a robust compound annual growth rate (CAGR) of 7.9% from 2019 to 2026. This growth is driven by increasing demands for advanced technology in sectors such as automotive, aerospace, and telecommunications. As manufacturers seek innovative ways to enhance productivity and reduce costs, exploring unique examples of cable harness assembly alternatives has become paramount. These alternatives not only drive efficiency but also contribute to improved reliability and performance of electronic devices, ultimately impacting the bottom line for businesses in a competitive market.

Advantages of Streamlined Cable Harness Assembly in Manufacturing

In the fast-paced world of manufacturing, streamlined cable harness assembly has emerged as a pivotal advantage for industry leaders looking to enhance efficiency. According to a 2022 report by Grand View Research, the global cable assembly market is projected to reach USD 220 billion by 2028, growing at a CAGR of 8.2%. This surge is largely attributed to the increasing demand for automated processes that reduce assembly time and labor costs. By adopting modular cable harness designs and automated assembly techniques, manufacturers can significantly decrease production time while maintaining high levels of quality control.

Furthermore, the advantages of streamlined assembly extend beyond mere financial savings. A study by the IPC (Institute for Printed Circuits) indicates that companies that implement efficient cable harness assembly techniques experience a 30% reduction in error rates and an increase in overall productivity by up to 25%. This not only accelerates time-to-market for new products but also enhances the reliability of complex electrical systems across various industries such as automotive, aerospace, and consumer electronics. Embracing innovations in cable harness assembly positions manufacturers to stay competitive in an ever-evolving market landscape.

Innovative Techniques to Enhance Cable Harness Efficiency

In the manufacturing sector, efficiency is paramount, and the cable harness assembly process is no exception. Innovative techniques have emerged to enhance this efficiency, significantly impacting production timelines and cost management. For instance, employing automation and robotics in cable harness assembly not only minimizes human error but also accelerates the assembly process, leading to higher throughput in manufacturing environments.

**Tips for Enhancing Cable Harness Assembly Efficiency:**

Utilizing advanced materials can greatly reduce weight and enhance flexibility, contributing to easier installations and durability. Moreover, incorporating modular designs allows for quicker adjustments and repairs, which can drastically minimize downtime during production.

Additionally, investing in training programs for employees ensures that personnel are adept in the latest techniques, which can lead to increased productivity and enhanced quality control. Embracing smart manufacturing technologies, such as IIoT integration, also empowers manufacturers to closely monitor and optimize their assembly processes in real-time, driving unmatched efficiency.

Case Studies: Success Stories in Cable Harness Assembly

In the realm of manufacturing, cable harness assembly plays a vital role in ensuring the seamless operation of electronic devices. Through various case studies, we can uncover how different companies have turned to innovative assembly techniques, driving both efficiency and quality in their productions. One such instance is a leading automotive manufacturer that revolutionized its assembly line by integrating automated tools and customized workflow designs. As a result, they significantly reduced assembly time while enhancing the precision of each harness, leading to a notable decline in defective products.

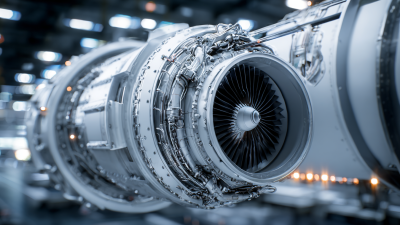

Another compelling example comes from the aerospace industry, where a major supplier implemented a modular approach to cable harness assembly. By organizing components into pre-assembled modules, they were able to simplify the integration process and expedite production cycles. This strategy not only improved efficiency but also allowed for easier troubleshooting and maintenance, providing a substantial competitive edge in a high-stakes market. The success stories from these industries highlight the transformative impact of intelligent design and technology in cable harness assembly, paving the way for future advancements in manufacturing.

Impact of Cable Harness Design on Production Speed and Cost

The design of a cable harness plays a crucial role in determining both production speed and overall manufacturing costs. When engineers meticulously plan the layout and selection of materials for cable harnesses, they can streamline the assembly process. For instance, pre-assembled harnesses, where cables are grouped and organized into a single unit, reduce the complexity of installation. This not only minimizes the time workers spend on assembly but also decreases the likelihood of errors, thereby enhancing overall productivity.

Moreover, the impact of innovative cable harness designs extends beyond just speed. By using modular designs, manufacturers can easily adapt to changes in production needs without incurring significant expenses. This flexibility allows teams to switch out components or scales as demanded by market trends. Consequently, thoughtful design choices lead to a decrease in waste and lower costs associated with rework or scrap materials, ultimately supporting a more efficient and cost-effective manufacturing environment.

Discovering Cable Harness Assembly: Unique Examples that Drive Efficiency in Manufacturing - Impact of Cable Harness Design on Production Speed and Cost

| Example Case | Production Speed (units/hour) | Cost per Unit ($) | Cable Harness Length (m) | Design Complexity (1-10) |

|---|---|---|---|---|

| Automotive Wiring | 45 | 75 | 5 | 7 |

| Aerospace Cabling | 30 | 200 | 12 | 9 |

| Consumer Electronics | 60 | 50 | 3 | 5 |

| Industrial Machinery | 25 | 120 | 10 | 8 |

| Telecommunications Equipment | 40 | 90 | 4 | 6 |

Future Trends in Cable Harness Technologies for Manufacturers

As the manufacturing landscape continues to evolve, cable harness technologies are at the forefront of innovations driving efficiency and productivity. The integration of smart manufacturing processes and materials has significantly enhanced the production of cable harnesses. For instance, the adoption of automation in assembly lines not only speeds up the process but also minimizes human error, ensuring high-quality output. Additionally, advancements in materials science have led to the development of lightweight, durable cables that improve the overall performance of electronic assemblies, benefiting industries ranging from automotive to aerospace.

Looking ahead, manufacturers are increasingly exploring the potential of IoT-enabled cable harnesses. This technology allows for real-time monitoring of cable performance and health, which can prevent failures before they occur. Furthermore, the trend towards modular designs is gaining traction, allowing manufacturers to customize harnesses more easily for various applications. By focusing on versatility and reliability, manufacturers can adapt more readily to market demands, ensuring they remain competitive in a rapidly changing environment. The future of cable harness technology not only promises improved efficiency but also paves the way for smarter, more resilient manufacturing practices.

Related Posts

-

Ultimate Guide to Cable and Harness Assembly Solutions for Global Procurement Success

-

Comparing Wire Harness Assemblies: Which Cable Solutions Meet Industry Standards Best?

-

10 Best Industrial Wire Trends You Should Know in 2023

-

Innovative Applications of Best Wire Assemblies in Aerospace Industry

-

Innovative Electrical Harness Solutions for Automotive Challenges in Global Supply Chains

-

The Ultimate Guide to Choosing the Right Electrical Wire Connector for Your Projects

© 2023 JEM Electronics, Inc. – United States Cable Assembly. All rights reserved.