Blog

Top 10 Cable and Harness Assembly Techniques You Need to Know

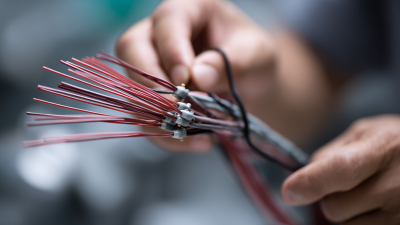

In the world of electronics and machinery, the importance of effective cable and harness assembly cannot be overstated. As industries strive for reliability and efficiency, the techniques used in assembling these vital components play a critical role in ensuring that devices function optimally. This article delves into the top ten cable and harness assembly techniques you need to know, equipping you with the knowledge to enhance both the performance and durability of your assemblies.

Understanding the intricacies involved in cable and harness assembly is essential for engineers and technicians alike. From choosing the right materials to employing precise assembly methods, each step can significantly impact the overall quality and reliability of the final product. By exploring these key techniques, you will be better prepared to tackle challenges in the assembly process and implement best practices that lead to superior outcomes. Whether you're a seasoned professional or new to the field, mastery of these assembly techniques is vital for anyone involved in cable and harness assembly.

Essential Principles of Cable and Harness Assembly Techniques

Cable and harness assembly is a fundamental aspect of the electrical and electronics manufacturing sectors. Understanding the essential principles behind these techniques is crucial for ensuring optimal performance and reliability in various applications, from automotive to aerospace. According to a report by the IPC Association Connecting Electronics Industries, improper assembly techniques can lead to a 30% increase in failure rates in electronic systems, highlighting the importance of mastering the right practices.

One of the core principles in cable and harness assembly is the significance of proper cable management. Techniques such as bundling, braiding, and using heat-shrink tubing not only enhance the aesthetic of the assembly but also play a critical role in protecting wires from abrasion and environmental stressors. The Decision-Making Framework developed by NASA outlines how effective cable management can reduce maintenance costs by up to 20% while increasing the lifespan of the harnesses. This emphasizes the need for assembly technicians to be well-versed in these techniques to ensure functionality and longevity.

Moreover, attention to detail in terminations and connections cannot be overstated. The quality of terminations directly impacts electrical performance and reliability. Research indicates that nearly 60% of electrical failures can be traced back to inadequate connections. Implementing best practices such as proper crimping techniques and ensuring compliance with industry standards can mitigate these risks. Ultimately, adhering to these essential principles not only drives efficiency but also safeguards the integrity of the final product.

Understanding Different Types of Cables and Their Applications

When it comes to cable and harness assembly, understanding the different types of cables and their specific applications is crucial for ensuring optimal performance and reliability. Various cables serve unique purposes depending on their construction and intended use. For instance, power cables, typically designed to transmit electricity, are essential in both industrial and residential settings. These cables are often insulated and can withstand high voltage levels, making them vital for safety and efficiency in electrical systems.

Data cables, on the other hand, play a significant role in telecommunications and networking industries. These cables, such as Ethernet and fiber optic cables, are designed to facilitate high-speed data transmission. The choice of cable often depends on the required bandwidth and distance of transmission, with fiber optic cables offering superior performance over longer distances due to their ability to transmit light signals at high speeds with minimal loss. Understanding the characteristics of these different cables allows engineers and technicians to select the proper assembly techniques tailored to their specific applications, ensuring reliable connections in diverse environments.

Step-by-Step Process for Accurate Cable Stripping and Termination

Effective cable stripping and termination are crucial steps in the cable and harness assembly process, ensuring reliability and performance in electrical connections. To begin with, proper cable stripping techniques require precision tools and a steady hand. Using a high-quality cable stripper allows for consistent, clean cuts that prevent damage to the inner conductors. It’s essential to measure the required length before stripping to avoid excessive exposure of wires, which can lead to potential short circuits or interference.

Once stripped, termination involves connecting the conductors to connectors or terminals securely. This process can vary depending on the type of connection required, be it soldering, crimping, or using insulation displacement connectors. When crimping, for instance, it’s vital to select the correct die and apply even pressure to ensure a firm hold while avoiding damage to the wire. Additionally, testing the connections with a multimeter post-termination is a good practice to ensure that the assembly performs as expected. Following these step-by-step procedures enhances the quality of cable assemblies and minimizes the risk of failure in the field.

Top 10 Cable and Harness Assembly Techniques

This chart displays the top 10 cable and harness assembly techniques along with the expertise level required for each technique. A higher score indicates greater skill and understanding necessary to execute the task accurately.

Best Practices for Harness Layout and Design

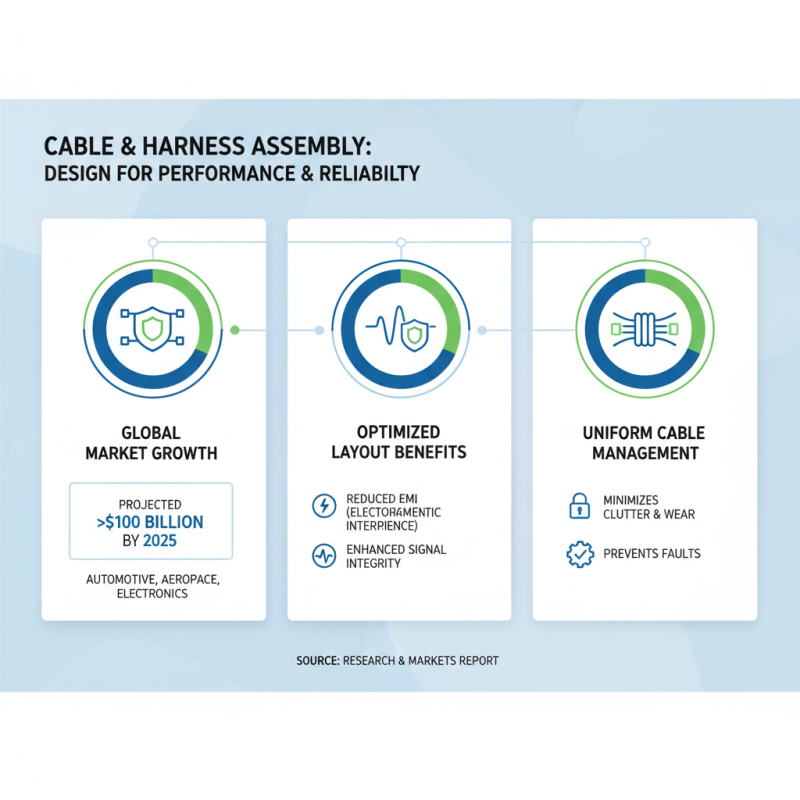

When it comes to cable and harness assembly, effective design and layout are crucial for optimizing performance and reliability. According to a report by Research and Markets, the global wire harness market is projected to surpass $100 billion by 2025, highlighting the growing importance of efficient harness design in various industries, such as automotive, aerospace, and consumer electronics. Best practices in harness layout significantly contribute to minimizing electromagnetic interference (EMI) and enhancing signal integrity. A uniform cable management system, which organizes and secures cables, is essential for reducing clutter and the chance of faults due to cable wear and tear.

Moreover, strategic layout planning can lead to significant cost reductions. The IPC-9592 standards suggest that a well-organized harness design can reduce manufacturing errors by up to 30%, as workers are able to quickly identify and correct issues during assembly. Implementing proper spacing and routing techniques ensures that cables are protected from heat sources and mechanical stress, thereby increasing their lifespan. Emphasizing these best practices not only improves the overall quality of harness assemblies but also leads to greater efficiency in production processes across multiple sectors.

Common Challenges in Cable Assembly and How to Overcome Them

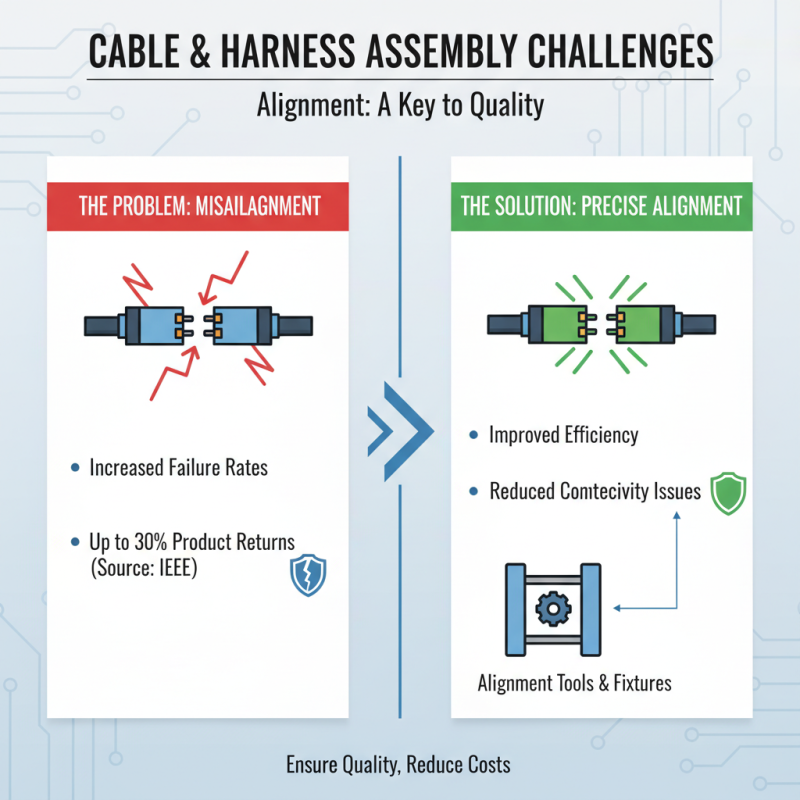

In the realm of cable and harness assembly, various challenges can arise, affecting both efficiency and product quality. One of the most common issues is misalignment during the assembly process, which can lead to increased failure rates. In fact, studies from the Institute of Electrical and Electronics Engineers (IEEE) suggest that misalignment can result in an up to 30% increase in product returns due to connectivity issues. To overcome this, implementing precise alignment tools and fixtures is crucial, ensuring that each component is correctly positioned before the assembly process begins.

Another significant challenge involves managing the harsh environmental conditions that many cable assemblies operate in. Factors such as temperature fluctuations, moisture, and vibrations can adversely affect cable performance. According to a report by the International Electrotechnical Commission (IEC), about 40% of failures in cable assemblies can be attributed to environmental stress. Utilizing high-quality materials specifically designed to withstand these conditions, along with thorough testing protocols, can mitigate these risks. Additionally, regular maintenance and inspections play a vital role in identifying potential issues before they escalate, ensuring a longer lifespan for the assembled products.

Related Posts

-

Comparing Wire Harness Assemblies: Which Cable Solutions Meet Industry Standards Best?

-

2025 How to Optimize Cable and Harness Assembly for Maximum Efficiency

-

What is Cable Assembly and How is it Used in Modern Technology

-

2025 Market Insights: 5 Essential Tips for Succeeding in Best Wire Harness Assembly

-

7 Essential Tips for Optimizing Your Cable and Harness Assembly Efficiency by 30% in 2023

-

How to Efficiently Design Your Own Wire Harness Assembly

© 2023 JEM Electronics, Inc. – United States Cable Assembly. All rights reserved.