Blog

10 Best Industrial Wire Trends You Should Know in 2023

As we navigate through 2023, the industrial wire sector is poised for significant advancements, driven by evolving technologies and market demands. According to Research and Markets, the global industrial wire market is expected to grow at a CAGR of 5.3% from 2021 to 2026, reaching approximately $80 billion. This growth is largely attributed to the increasing automation in manufacturing processes and the rising demand for high-performance wire solutions across various industries, including automotive and construction. In this dynamic landscape, staying informed about the latest trends in industrial wire is crucial for industry professionals.

This blog will explore the ten best industrial wire trends that you should know in 2023, providing you with essential insights and tips to leverage these developments effectively in your operations.

Emerging Technologies Influencing Industrial Wire Design in 2023

In 2023, the industrial wire industry is witnessing a significant transformation driven by emerging technologies. One of the most notable trends is the integration of smart materials that enhance performance and durability. These materials not only offer increased resistance to harsh environmental conditions but also align with the rising demand for sustainability. Innovations in wire insulation, such as the use of bio-based polymers, are paving the way for more environmentally friendly solutions without compromising on functionality.

Another critical influence on industrial wire design is the rise of automation and IoT connectivity. As factories become smarter, the need for wires that facilitate seamless communication between machines and systems has become paramount. Manufacturers are increasingly adopting advanced sensors and monitoring systems integrated directly into the wire design, enhancing operational efficiency and predictive maintenance capabilities. This shift not only optimizes workflow but also minimizes downtime, making technology a key player in the evolution of industrial wiring solutions.

10 Best Industrial Wire Trends You Should Know in 2023

| Trend | Description | Impact on Design | Emerging Technologies |

|---|---|---|---|

| Sustainability | Increased focus on eco-friendly materials and production processes. | Designs are evolving to incorporate recyclable materials. | Biodegradable plastics, renewable energy integration. |

| Smart Wiring | Integration of sensors within wire systems for real-time monitoring. | Enhanced safety and efficiency through data collection. | IoT devices, machine learning algorithms. |

| Cable Management Innovations | Improved designs for ease of installation and maintenance. | Reduction in downtime during service and upgrades. | 3D printing, modular design concepts. |

| Lightweight Materials | Transitioning to lighter materials to enhance efficiency. | Increased flexibility in wire routing and handling. | Composites, advanced alloys. |

| Cybersecurity in Wire Design | Incorporation of cybersecurity features to protect data integrity. | Enhanced robustness in the design of wire systems. | Encryption technologies, secure communication protocols. |

| Advanced Insulation | Improved insulation materials for better performance. | Greater durability and temperature resistance. | Nanotechnology, thermoplastic elastomers. |

| Automation and Robotics | Use of automated systems in manufacturing wire products. | Streamlined production efficiency and accuracy. | Robotic assembly lines, AI controlling systems. |

| Custom Wire Solutions | Tailor-made wire products for specific industrial applications. | Enhances compatibility with unique machinery and setups. | Advanced CAD design tools, rapid prototyping. |

| Enhanced Safety Standards | Implementation of stricter safety guidelines for wire usage. | Increased focus on user safety and compliance. | Regulatory technologies, compliance monitoring tools. |

Sustainable Materials and Their Impact on Wire Manufacturing

In 2023, the focus on sustainable materials in wire manufacturing is paving the way for significant advancements in the industry. As environmental concerns gain traction, manufacturers are increasingly adopting eco-friendly materials that reduce environmental impact without compromising quality. This shift is not only crucial for sustainable development but is also becoming a competitive differentiator in the market.

Tips for manufacturers include evaluating the lifecycle of materials—considering both sourcing and disposal to ensure sustainability throughout. Emphasizing transparency in material sourcing can also build trust with consumers who are becoming more eco-conscious. Moreover, investing in innovative recycling technologies can help manufacturers minimize waste and recover valuable resources, thus enhancing efficiency and sustainability.

It's essential to stay informed about the latest trends in sustainable materials, such as biodegradable plastics and recycled metals. By prioritizing these materials, manufacturers can align their practices with contemporary environmental standards while meeting the evolving demands of consumers looking for greener alternatives in industrial wire products.

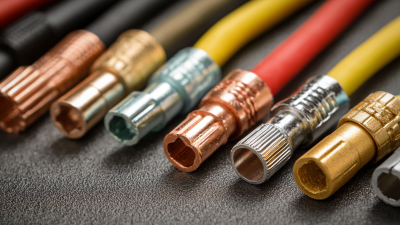

Innovative Wire Insulation Techniques for Enhanced Performance

In 2023, innovative wire insulation techniques have taken center stage as industries seek to enhance the performance of electrical systems under increasing operational stresses. With the growing demand for high-power dense electrical machines, the challenges posed by electrical, mechanical, and thermal stresses have prompted substantial advancements in wire insulation materials. Notably, studies on high-voltage direct current (HVDC) transmission systems highlight the critical role of insulation materials in mitigating space charge accumulation, which can significantly affect system efficiency and longevity.

Recent innovations such as silicone rubber nanocomposites, enhanced with nano-TiO, demonstrate improved insulation performance while maintaining flexibility and durability. These advancements not only address the immediate electrical insulation requirements but also contribute to energy efficiency through superior thermal management capabilities. As researchers continue to explore the integration of cutting-edge materials and methodologies in wire insulation, industries are poised to benefit from stronger, more reliable electrical systems that align with sustainable building practices and energy-efficient constructions, marking a crucial step toward meeting future energy demands.

Automation and Smart Manufacturing Trends in the Wire Industry

As we navigate through 2023, the wire industry is at the forefront of automation and smart manufacturing trends. The Manufacturing Execution Systems (MES) market is set for significant expansion, driven by the growing need for real-time data analytics. This technological evolution not only streamlines manufacturing processes but also enhances operational efficiency across various sectors.

Moreover, the copper wire market is projected to experience substantial growth. With a market size estimated at USD 149.12 billion in 2024, it is expected to reach USD 210.79 billion by 2030, showcasing a robust compound annual growth rate (CAGR). Instrumentation cables are also on a growth trajectory, with projections indicating an 8.2% CAGR from 2025 to 2032, potentially surpassing USD 19.19 billion by 2032.

**Tips:** Embracing advanced manufacturing technologies can lead to significant cost reductions and improved product quality. Companies should invest in data analytics to enhance decision-making processes. Additionally, staying abreast of market trends will help businesses identify new opportunities and adapt to shifting consumer demands.

10 Best Industrial Wire Trends in 2023

Safety Standards and Regulations Shaping the Future of Industrial Wiring

In 2023, safety standards and regulations are pivotal in shaping the future of industrial wiring, driving innovation and adherence to best practices. The continuous evolution of safety standards, such as the National Electrical Code (NEC) and International Electrotechnical Commission (IEC) guidelines, ensures that industrial wiring meets both operational and safety requirements. With the integration of advanced technologies such as IoT and smart systems, compliance has become increasingly complex, necessitating a thorough understanding of these regulations among industry professionals.

Furthermore, the rise of sustainability in industrial practices has prompted regulatory bodies to establish stricter guidelines concerning energy efficiency and environmental impact. Manufacturers are now focusing on eco-friendly wiring solutions, which are not only compliant with safety standards but also contribute to reducing the carbon footprint of industrial operations. This shift encourages the adoption of safe and efficient wiring systems that prioritize both human safety and environmental responsibility, ultimately fostering a safer and more sustainable future in industrial settings.

Related Posts

-

2025 Market Insights: 5 Essential Tips for Succeeding in Best Wire Harness Assembly

-

Ultimate Guide to Cable and Harness Assembly Solutions for Global Procurement Success

-

The Ultimate Guide to Choosing the Right Electrical Wire Connector for Your Projects

-

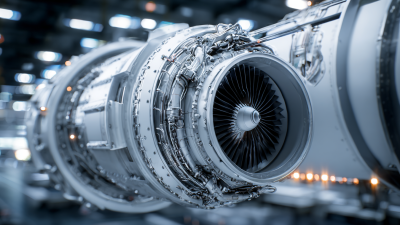

Innovative Applications of Best Wire Assemblies in Aerospace Industry

-

Innovative Electrical Harness Solutions for Automotive Challenges in Global Supply Chains

-

Comparing Wire Harness Assemblies: Which Cable Solutions Meet Industry Standards Best?

© 2023 JEM Electronics, Inc. – United States Cable Assembly. All rights reserved.